Iron Ore Smelting Techniques: A Comparative Study

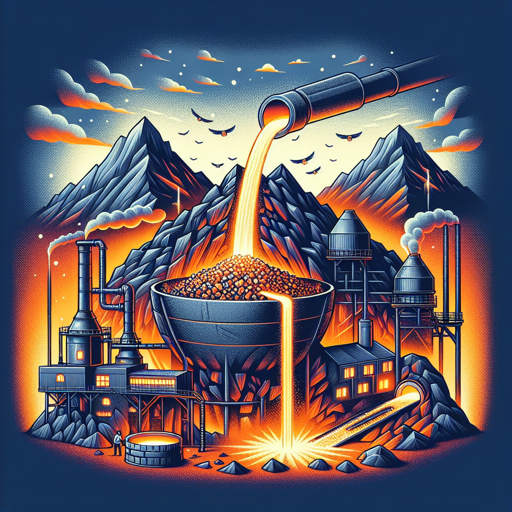

An in-depth exploration of traditional and modern methods used in iron ore smelting.

Introduction

Iron, a lustrous, malleable, silver-grey metal, has been a cornerstone of human civilization for thousands of years. Its use in tools, weapons, and construction materials has shaped the course of history. This article delves into the fascinating world of iron ore smelting, exploring both traditional and modern techniques used to transform raw iron ore into usable iron.

Traditional Smelting Techniques

Bloomery

The earliest method of smelting iron ore was the bloomery, a furnace made from clay or mud and straw. The iron ore and charcoal were placed inside, and the furnace was heated to high temperatures. The iron ore would melt and separate from the impurities, forming a ‘bloom’ of sponge iron.

| Process | Materials Used | Temperature | Output |

|---|---|---|---|

| Bloomery | Iron ore, Charcoal | 1,100 - 1,150°C | Sponge Iron |

Blast Furnace

By the late Middle Ages, the bloomery was replaced by the more efficient blast furnace. Iron ore, limestone, and charcoal were layered inside the furnace. The furnace was then heated to temperatures over 1,500°C, resulting in the formation of molten iron, or ‘pig iron’.

| Process | Materials Used | Temperature | Output |

|---|---|---|---|

| Blast Furnace | Iron ore, Limestone, Charcoal |

|

Pig Iron |

Modern Smelting Techniques

Electric Arc Furnace

The electric arc furnace is a modern method of smelting iron ore. It uses high-voltage electric arcs to melt the iron ore. The process is highly controlled, resulting in a more pure iron output than traditional methods.

| Process | Materials Used | Temperature | Output |

|---|---|---|---|

| Electric Arc Furnace | Iron ore, Electric Current | Varies | Pure Iron |

Direct Reduced Iron (DRI)

Direct Reduced Iron (DRI) is another modern method of smelting iron ore. It involves heating the iron ore with natural gas in a low-oxygen environment to extract the iron.

| Process | Materials Used | Temperature | Output |

|---|---|---|---|

| Direct Reduced Iron (DRI) | Iron ore, Natural Gas | 800 - 1,000°C | Pure Iron |

“The history of iron smelting is a testament to human ingenuity and the relentless pursuit of progress.” - Anonymous

External Reference

For further reading on iron smelting techniques, refer to this detailed article from the National Museum of Iron.

Conclusion

From the ancient bloomeries to the modern electric arc furnaces and DRI methods, the techniques of iron ore smelting have evolved significantly over the centuries. Each method has its unique strengths and weaknesses, reflecting the technological advancements and resources available at different points in history. As we continue to advance, who knows what the future holds for iron ore smelting? One thing is for certain - our quest for better, more efficient methods to harness the valuable resource that is iron will continue unabated.